## Introduction

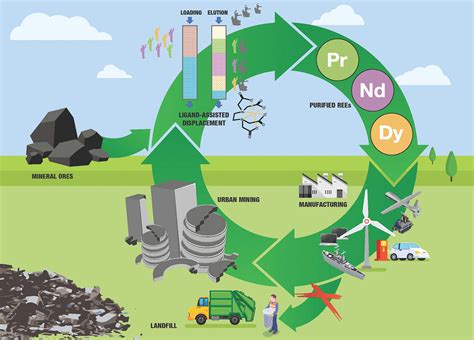

Landfills, while crucial for waste management, pose significant environmental concerns due to the leachate they generate. This liquid, formed from the decomposition of waste, contains a variety of chemicals and heavy metals, including rare earth metals. These metals are highly sought after for their use in technology, energy, and other industrial applications. Extracting rare earth metals from landfill leachate presents a promising solution to both waste disposal and resource recovery challenges. This article explores the methods and processes involved in extracting rare earth metals from landfill leachate.

## The Importance of Rare Earth Metals

Rare earth metals are a group of 17 metallic elements with unique magnetic, luminescent, and thermal properties. They are essential for a range of high-tech applications, such as wind turbines, electric vehicles, and smartphones. Despite their name, these metals are not as rare as they once were, but the mining and processing of these metals are expensive and environmentally harmful.

## Challenges of Extracting Rare Earth Metals from Landfill Leachate

Extracting rare earth metals from landfill leachate presents several challenges. The concentration of these metals in leachate is typically low, and the presence of other contaminants can hinder the extraction process. Additionally, the high cost of extraction methods and the potential environmental impact must be carefully considered.

## Extraction Methods

### 1. Adsorption

Adsorption is a common technique for extracting metals from water. It involves passing the leachate through a medium, such as activated carbon or resin, which has a high affinity for the target metals. The metals bind to the medium, allowing for easy separation and recovery.

### 2. Membrane Filtration

Membrane filtration uses specialized membranes to separate the desired metals from the leachate. The pores in the membrane are designed to allow only the metals to pass through, while blocking other contaminants. This method is effective for removing trace amounts of metals.

### 3. Chemical Precipitation

Chemical precipitation involves adding a precipitating agent to the leachate to form a solid that can be separated and processed. The precipitating agent reacts with the rare earth metals to form a metal hydroxide, which can then be separated from the rest of the solution.

### 4. Bioleaching

Bioleaching uses microorganisms to break down the metals into a form that can be easily extracted. The microorganisms use the metals as an energy source, and the resulting metal-rich solution can be treated further to recover the metals.

## Considerations for the Extraction Process

When extracting rare earth metals from landfill leachate, several factors must be considered:

– **Purity**: The purity of the extracted metals is crucial for their use in industrial applications. Purification methods must be used to remove any remaining contaminants.

– **Cost**: The cost of the extraction process must be economically viable. This includes the cost of equipment, chemicals, and labor.

– **Environmental Impact**: The extraction process must minimize the environmental impact. This includes reducing emissions and waste generation.

## Conclusion

Extracting rare earth metals from landfill leachate is a promising approach to addressing both waste disposal and resource recovery challenges. While the process presents several challenges, innovative methods and careful consideration of environmental and economic factors can make it a viable solution. As technology continues to advance, the extraction of valuable metals from waste will become increasingly important in the pursuit of a sustainable future.